Inventors

OLGA GRZHIBOVSKAYA

Rybinsk inventors share their experience of creating an effective company and identifying development prospects

An innovative enterprise operates in Rybinsk, whose developments and equipment are used in hazardous chemical industries in Russia. The project developed by the employees won the competition in Skolkovo, and the technology they created is designed to clean up Lake Nero from pollution.

We are talking about the company “KhimPromEngineering”.

Team

Exactly seven years ago, in June 2013, Rybinsk residents Sergey Sosedov and Alexey Afanasyev founded an engineering company. She joined the KhimPromGroup holding, which is engaged in the integrated design of industrial enterprises.

At that time, both founders of the new company were experienced managers. Sergey Sosedov was involved in business for a long time, heading the design institute “Rezinoasboproekt”, and later the design and construction company “KhimPromProekt”. Alexey Afanasyev worked as director of science and innovation, even earlier he taught at the Aviation Technology Institute, and was seriously involved in science. The candidate of technical sciences has several dozen copyright certificates and patents.

— In the early 2010s, a need arose to equip the enterprises being designed with the technological equipment necessary for the introduction of new production processes. For such problems, standard solutions are often unsuitable or absent altogether. It was for the development of non-standard, unique equipment, as well as for the management of complex projects for the creation of industrial production, that our company was founded,” says Ivan Afanasyev, development director.

Creative, inventive, essentially R&D work required the formation of a separate team of highly qualified engineers and mechanical designers.

“In Rybinsk, and indeed in the country in general, there was a shortage of professionals,” the manager recalls. – The crisis of the 90s significantly affected the quality and quantity of specialists in the labor market. And only now the situation is slowly starting to level out.

Despite all the difficulties, Alexey Afanasyev managed to assemble a team of professional inventors. The team included specialists who devoted most of their lives to industry, the development of new equipment and science.

The company currently employs eleven employees. And three of them are Afanasyevs. Following their father Alexey Gavriilovich, his children entered the engineering business.

“This helps in resolving some issues,” admits Ivan Afanasyev. – The big advantage is that there is no unnecessary formalization; urgent issues can be resolved at any time, in any situation. For both me and my father, this is already a way of life; we have no division into working and non-working time. However, there is another side to the coin. Industrial disputes must not be allowed to interfere with family life and spoil relationships.

Dangerous chemistry

The start of the company turned out to be quite successful. Among the first orders is reactor equipment for instrumentation of production facilities using acids and their mixtures. Over seven years, the portfolio of the company and team members has accumulated dozens of patents for inventions, including several Eurasian ones. Most of the developments are equipment for grinding and mixing various materials, the range of which is quite wide. Such solutions are in demand in many industries: from metallurgy to pharmaceuticals.

One of the inventions of the Rybinsk residents allowed the team to be among the winners of the competition of innovative projects in the field of mechanical engineering “Technostart-Skolkovo 2014” and Startup Tour, held in Yaroslavl in the same year.

“Our installation is distinguished by high grinding intensity,” says Ivan Afanasyev. – Its efficiency is higher due to continuous operation, high productivity with compact dimensions.

Nowadays people from many regions of Russia turn to the Rybinsk enterprise when new production facilities are being created or existing enterprises are being modernized. When the question arises about the development and implementation of new equipment and technologies. When the task is to make a modern analogue of Soviet or foreign equipment as part of import substitution. When an industrial enterprise requires design support to maintain operability or modernize existing equipment.

— Our main specialization is the development of non-standardized equipment and technological lines for the chemical industry. In the vast majority of cases, we deal with chemically hazardous production facilities, including those belonging to the first hazard class. And these are increased requirements for fire and explosion protection of equipment,” explains Ivan Afanasyev.

Large factories within state corporations are interested in the inventions of a small Rybinsk company. Such as the Tambov Powder Plant or the Aleksinsky Chemical Plant. In addition to special chemicals, there are customers from other industries: paint and varnish production, machine-building enterprises, foundries, mineral fertilizer plants.

— We have a lot of chemical production facilities in our country. But still, their number is limited, and modernization and technical re-equipment do not take place there very often. Therefore, entering the international market is a natural development option for our company,” says the director.

Ambitions and abroad

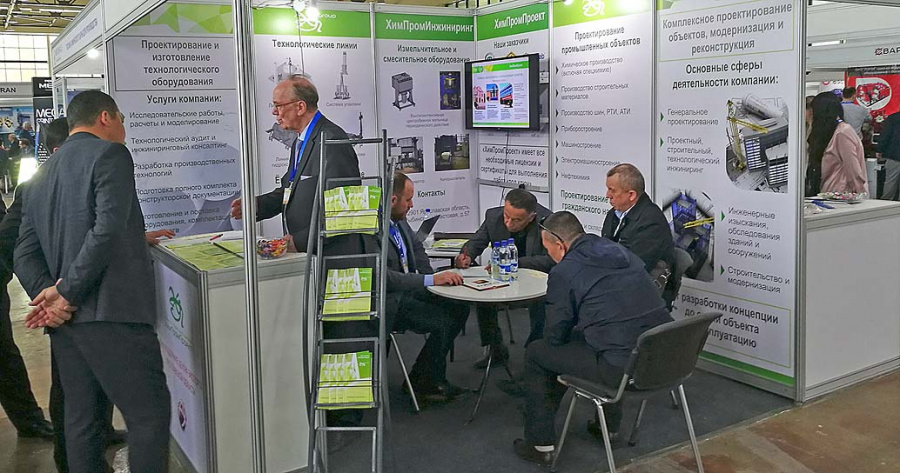

The inventors took their first steps towards foreign customers several years ago, when they began to participate in international exhibitions of innovation and technology in Iran, Cuba, India, Uzbekistan, and in the chemical industry and science exhibition “Chemistry-2019” in Moscow.

— Nowadays, Russian business faces a global task – the development of non-resource exports. And this is correct,” Ivan Afanasyev is convinced. – The qualifications of domestic technical specialists, in my opinion, are quite high. And this could become one of the significant export items.

However, experience shows that promoting engineering services abroad is the same as taking the unbeaten road.

“The main problem is related to the fact that this is not a specific product that can be seen in the catalog, ordered and purchased,” explains Afanasyev. – Marketing is very different: there are features of promotion, longer cycles of negotiations, consultations with the client, and approvals. We still have to learn all this. We are supported in this by the Yaroslavl Export Center and the Export School, where our General Director was trained.

One of the most ambitious tasks for Rybinsk residents is to learn how to effectively export engineering services and form a pool of foreign economic partners.

— For us, first of all, the former republics of the USSR are interesting – there are many industries there that are similar to Russian ones. In the longer term – countries where the Soviet Union built production enterprises, where our specialists are remembered and appreciated.

Purification technologies

However, Rybinsk inventors do not live by chemistry alone. They consider environmental topics interesting and promising.

“This includes the processing of sludge and sewage sludge, methods for localizing pollution, and technologies for the rehabilitation of reservoirs,” the development director lists the range of interests of the company. – In the near future, we plan to promote inventions that can be used at wastewater treatment plants of enterprises, in housing and communal services and aeration stations.

The Rybinsk enterprise has experience in developing environmental technologies. In 2017, the company took part in the preparation of proposals for the environmental rehabilitation of Lake Nero.

“We were faced with the task of identifying sources of pollution and neutralizing them. We proposed a method for localizing contaminants coming from tributaries, sewers and storm sewers. We hope that this technology will find application in the development of the Lake Nero cleansing project. The method, by the way, is universal and suitable for other bodies of water.

The future is “in one hand”

Trends in the engineering services market are set by customers, who push companies to develop an integrated approach to creating production facilities.

— We strive to provide a turnkey service, if it is necessary to design a production facility, equip it with equipment, and if what is required is not on the market, then develop it ourselves. Getting the result from “one source” is the most interesting format of cooperation for the customer,” explains the entrepreneur. — Another important vector of development is integrated project management. Large-scale projects often require the involvement of partners and co-executors. And the general contractor plays a huge role here, who manages the entire process and is responsible for it to the customer. We are currently working on two projects as a management company. And in the future we see this activity as one of the key ones for ourselves.

The main trend of the entire industry is the digitalization of production, the company believes. In design, this is expressed in the use of BIM technologies, which make it possible to create information models for managing the life cycle of an object at all stages of its existence.

“We intend to develop taking into account these trends, train employees, attract new specialists, use advanced software,” Ivan Afanasyev outlines the prospects. – Now we use tools such as three-dimensional modeling and use digital models in engineering calculations. But this, of course, is only the beginning of the movement into the digital future.

Link to the website of the newspaper “Rybinsk News”: gazeta-rybinsk.ru/2020/06/28/70418